The Use and Maintenance of Car Lift – Basic Knowledge Lecture II

Four Post Car Lift

Published in “Automotive Repair and Maintenance”

The hydraulic transmission four column lift is divided into wire rope traction and chain traction according to the traction method. The lifting tonnage is 3.5t, 4t, 5t, 6t, and 8t, and the platform length is 4.8m, 5.2m, and 5.7m. Among them, wire rope traction is the main market model. The four column lift can be operated by pressing the electric button for lowering or by pressing the manual unloading valve; The mechanical locking and unlocking methods for the four corners of the crossbeam are divided into manual pressing of the unlocking handle and pressing of the electric button to descend (delayed ascent, opening of the four corner electromagnet to open the safety); According to the layout form on the platform, it can be divided into three types: flat plate type, platform with side slip and corner plate (optional with one or two sets of intermediate secondary lifting carts), and platform with mother child secondary lifting platform (optional with side slip and corner plate).

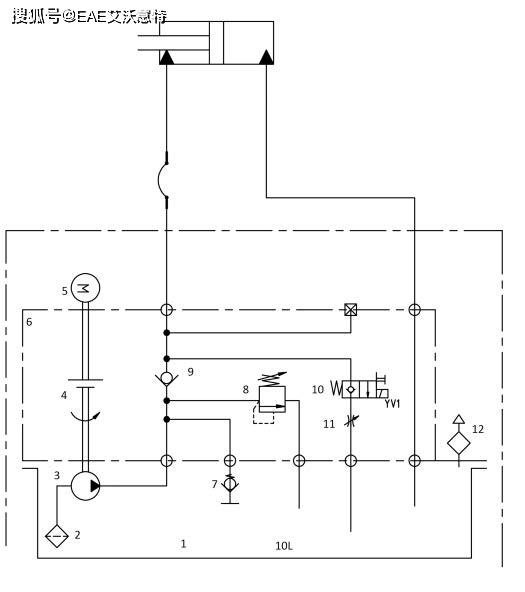

1.Principle of work

Figure 9:1. Fuel tank; 2. Filter screen; 3. Gear pump; 4. Couplings; 5. Motor; 6. Valve body; 7. Buffer valve; 8. Overflow valve; 9. One way valve; 10. Electromagnetic exchange

2.Key points of usage control

It is important to lubricate and maintain the steel wire rope used for traction and load-bearing purposes. Lubricating grease should be applied to the steel wire rope every month; Regularly inspect the wear and breakage of steel wire ropes. Improper use of steel wire ropes may cause local bending, twisting, and flattening; If there are more than 5 broken wires with a length of 60mm or more than 10 broken wires with a length of 300mm, they must be replaced; The steel wire is quite loose, with deep pits on the surface, steel core extrusion, cage like distortion in adjacent positions, and severe rusting and grinding of the steel wire, which must be replaced. The four pillars and two platforms must be leveled, with the four corners on the same horizontal plane. After adjustment, the steel wire rope nuts on the top plate of the pillars should be tightened. After leveling the platform, the four safety plates should be adjusted to ensure that the safety plates are pulled (manually) or the lowering button (electrically) is pressed, and the four corner safety plates are disengaged at the same time. The mechanical locking of any locking height is activated at the same time. After adjustment, the upper screw of the safety rod should be tightened with nuts. The steel wire rope guide wheel and guide wheel support shaft must be regularly lubricated with grease. When the wear gap between the guide wheel and the pulley shaft reaches 0.5mm, the pulley bushing must be replaced. If the shaft is severely worn, the shaft must be replaced at the same time.

3.Maintenance points

During daily operation, check the four corner safety lock blocks of the column to ensure both safety locking and simultaneous disengagement. If they are not synchronized, adjust the top wire rope connecting rod nut or the top nut of the safety plate to achieve this; Check for oil leakage at the connection joints of the hydraulic pipes and whether the oil cylinder is leaking oil. Check the flexibility of the unlocking mechanism and operating handle every month; Check if the connecting bolts between the platform and the crossbeam are loose. Check the tightness of the expansion bolts and the wear of the steel wire rope under the four columns every six months; Check the lubrication of the pulleys and pulley shafts at both ends of the main platform and crossbeam, add lithium based grease to each oil nozzle on time, inspect the surface of the steel wire rope, and replace it if it meets the replacement conditions proposed for use and control. Replace the hydraulic oil, clean the oil tank and filter screen after six months of initial use, and replace the hydraulic oil every year or 3000 times after operation; When replacing seals in oil cylinders, cleaning and replacing parts inside hydraulic pump stations, replacing wire ropes and pulleys, or installing and relocating equipment, professional maintenance personnel authorized by the equipment manufacturer should be responsible. Electrical maintenance should be carried out by qualified electricians according to the product manual.